Air Content of Concrete Pressure Method ( ASTM C - 231 )

Air Content of Concrete by Pressure Method

ASTM C - 231

Introduction

In this test, we will determine the air content in normal and heavy-weight concrete

If the air content increases 1% above the design value the strength reduction will be 3 to 5%

Apparatus

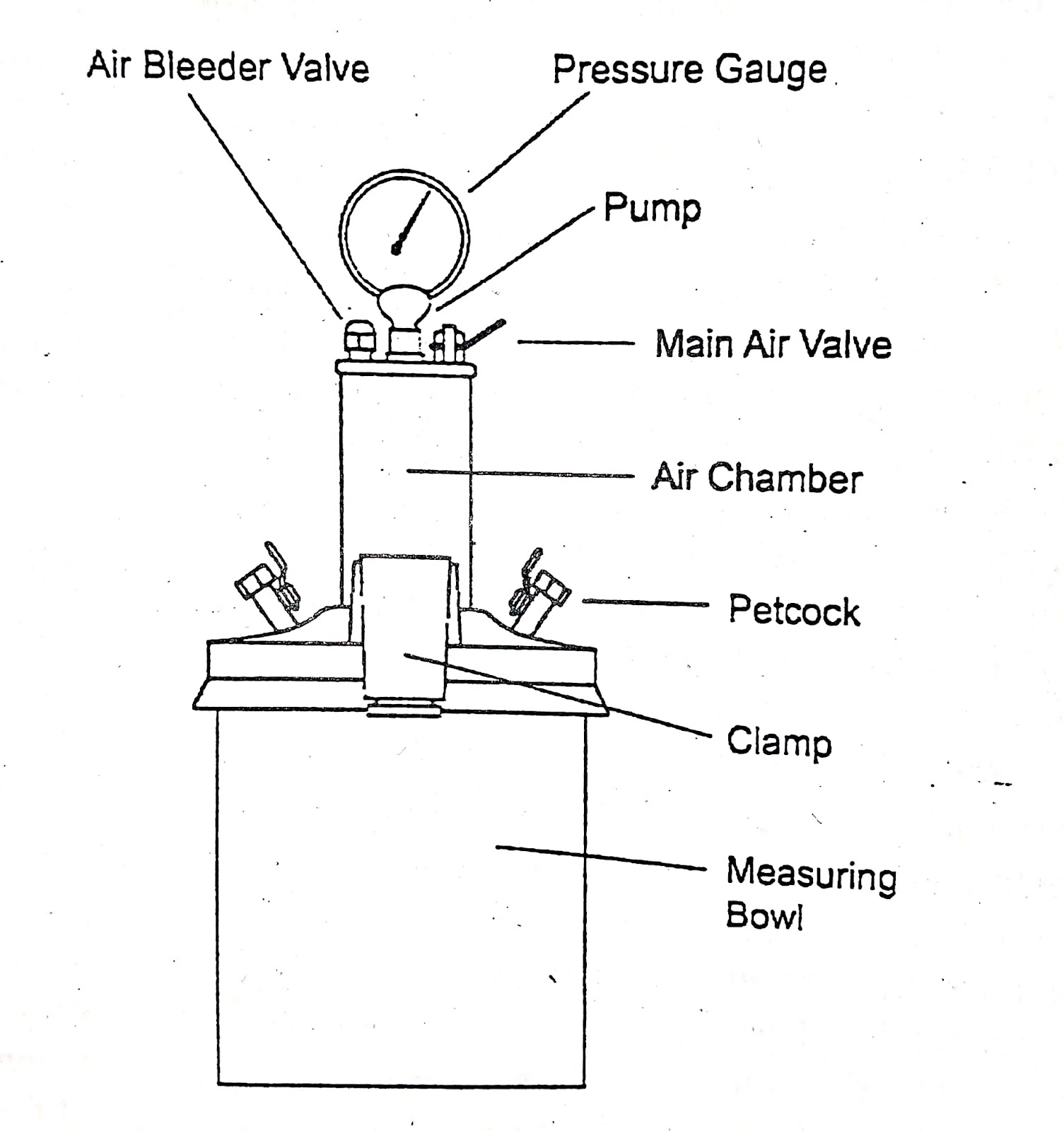

Meter Type A, Cover assembly fitted air valve, air bleeder valve, petcocks for bleeding off, main air valve

Cylindrical Container, Diameter equal to 0.75 to 1.25 times the height, capacity at least 0.2 cubic feet

Temping Rod, Hemispherical tip, diameter 16 + 2 mm, height 100 mm greater than the bowl

Internal vibrator, diameter 19 to 38 mm, frequency 7000 per min.

Strike off Plate, Thick 12 mm, length, and width 50 mm greater than the measure

Mallet, 600 + 200 grams

Rubber Syringe

Internal Vibrator or Temping Rod

If the slump is greater than 75 mm, using a rod

If the slump is 25 to 75 mm, using the rod or vibrator

If the slump is less than 25 mm, using a vibrator

Procedure of Temping Rod

Dampen the container with water, fill the concrete in a cylindrical container with three layers of equal volume

A first layer, rodding 25 times through its depth, tap the container 10 to 15 times with a mallet

A second layer, rodding 25 times through the previous layer approximately 25 mm, tap the container 10 to 15 times with a mallet

A third layer, rodding 25 times through the previous layer approximately 25 mm, tap the container 10 to 15 times with a mallet

Procedure of Internal Vibrator

Dampen the container with water, fill the concrete in a cylindrical container with two layers of equal volume

Insert the vibrator at three different points in each layer

Ensure the vibrator does not rest or touch the bottom or sides of the container

Compacting the final layer insert the vibrator through the previous layer approximately 25 mm

Vibrate in the concrete until the depression is left from the surface of the concrete, Over vibration may cause segregation

Surface Leveling

Remove all excess concrete from the top of the container with a trowel or other tools

Strike off the surface of the concrete and finish it smoothly with a strike-off plate

Procedure Meter Type A

Clamp the cover assembly to the container ensuring a pressure-tight seal and open both petcocks

Inject water from one petcock with a rubber syringe until water emerges from the opposite side of the petcock

Tight the air bleeder valve and pump the air in the air chamber until the dial gauge reach on initial pressure indication line

Allow few seconds compress air to cool, and stabilize the gauge on the initial pressure line by bleeding valve, pumping, or tapping the gauge by hand

Close both petcocks and tap the side of the container with a mallet, Press the main air valve and release the pressure in a container

Report the air content nearest 0.1 % using the aggregate correction factor

Calculation

Air content = Apparent Air Content - Aggregate Correction Factor

Comments

Post a Comment