Slump Test of Freshly Hydraulic Mix Concrete (ASTM C-143)

Slump Test of Freshly Hydraulic Mix Concrete

(ASTM C-143)

Introduction

The slump test is to determine the consistency of concrete, water content increase or decrease the cause of slump increase or decrease

Many other factors can change slump without changing in water content in concrete

Such as aggregate properties, grading, mix proportion, air content, concrete temperature, or add mixture

Apparatus

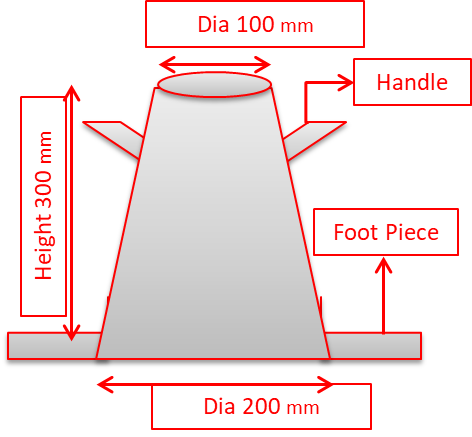

Frustum Cone

Temping Rod, Diameter 16 + 2 mm, Height 400 to 600 mm

Measuring Device

Procedure

Dampen the cone and base plate and place it flat and free of vibration surface

Clamp the cone with a base plate or technician standing of two-foot pieces

Fill the slump cone in three layers of even concrete distribution:

Fill the first layer from the bottom to 70 mm, Roding 25 times through its depth

Fill the second layer from the first layer to 160 mm, Roding 25 times through the previous layer approximately 25 mm

Fill the third layer from the second layer to the top of the cone, Roding 25 times through the previous layer approximately 25 mm

Excess concrete remove from the top of the cone by rolling motion of the temping rod

Raising the cone from the concrete carefully in a vertical direction within 5 + 2 seconds

Measure the slump from the top of the cone to the center top of the concrete

Report slump in inches or millimeters nearest 1/4 in. 5 mm

Comments

Post a Comment